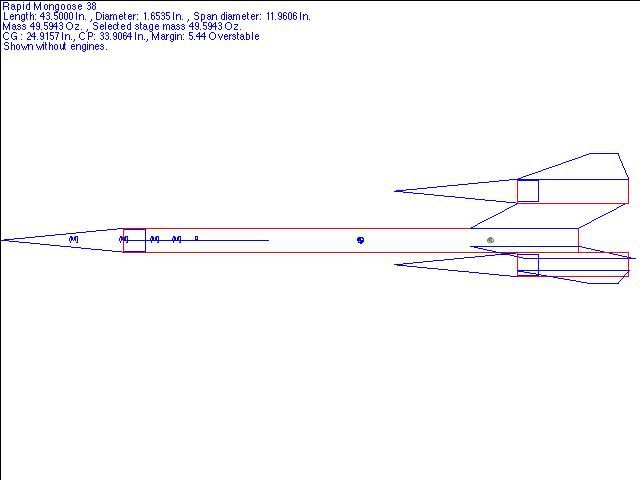

I had an unbuilt 38mm Mongoose kit lying around and decided to do something different with it to make the build a little more challenging. I came up with the idea of a central 6GXL 38 surrounded by 3 38mm pods that will hold 2 GR CTI motors. Basically a 4x min diameter project, looking to hit 22k Plus in the sims. Should be done by MHM hopefully along with my L# project. Anyhow here's the link to the build thread:

http://tqc.yuku.com/topic/3152

-Sean 😈

For kicks I'll try to see if I can embed photos how I was doing on the other site, let's see if this works...

ahh crap it did work. Well at least now I figured out how to have photos on this site. Anyhow there are a lot more photos on the other thread and I'll continue the build there. Maybe we could open a current project page on our site though so NCR members can do the same thing as that site. Shouldn't be hard, just an extra tab under the index. -Sean 8)

Even with the high ignition reliability of CTI, I'd highly recommend moving the outboards adjacent to the central motor to eliminate any effects of off-axis thrust.

Looks cool. Kind of like you peeled the 4" outer skin off my 4x38 bird!

Looking forward to this one!

Ken

Yeah I'm worried about the off-axis thrust myself. I talked to Dr J at CTI about using 2 ignitors for redundancy and he said there was no problem with doing that in the CTI motors. I'll probably run dual ignitors in every motor and then have them wired to 2 different sets of wires. Once I get the final weight for the sim I'm going to run different scenarios to see what may happen. This will definitely be a "heads up!!!!" flight.

-Sean

I talked to Dr J at CTI about using 2 ignitors for redundancy and he said there was no problem with doing that in the CTI motors.

Some remarks:

-1- You can do that, but make sure you check the throat clearance. Don't do it in the smallest motors that hardly take a single igniter.

-2- Never mix igniters that we supply. For smaller motors we use mini igniters. (Some Pro29 and Pro38 motors use these). They look very similar.

-3- If you want to maximize the chance of the motors lighting dual igniters are certainly a good idea. I had about 3 or 4 bad e-matches in the last year of testing (we fired around 1200 motors). Inspect the e-matches before using them and make sure both sides are soldered, and that there is no solder-blob between both sides of the circuit board shortening the fuse head. We have seen this.

-4- To further improve igniter reliability, you can do the following (not needed for motors that are not clustered):

- Remove the top grain and remove the pellet using a pen/stick (carefully).

- Re-install the top grain (note the bevel orientation).

- Run the e-match wires through the nozzle up, so they stick out of the frond end of the motor.

- Fold the match-head down into the pellet and run the wires on each side of the pellet.

- Re-install the pellet. The wires will sit between the propellant and the pellet.

This prevents igniters from falling down away from the pellet because of wind gusts, tripping on the wires etc.

Hope this helps. Good luck with your flight!

Jeroen

Dr J.,

4- To further improve igniter reliability, you can do the following (not needed for motors that are not clustered):

- Remove the top grain and remove the pellet using a pen/stick (carefully).

- Re-install the top grain (note the bevel orientation).

- Run the e-match wires through the nozzle up, so they stick out of the frond end of the motor.

- Fold the match-head down into the pellet and run the wires on each side of the pellet.

- Re-install the pellet. The wires will sit between the propellant and the pellet.

This prevents igniters from falling down away from the pellet because of wind gusts, tripping on the wires etc.

This sounds like the right way to do upper stages, too.

Ed

(we fired around 1200 motors).

I'm envious 😯

JW