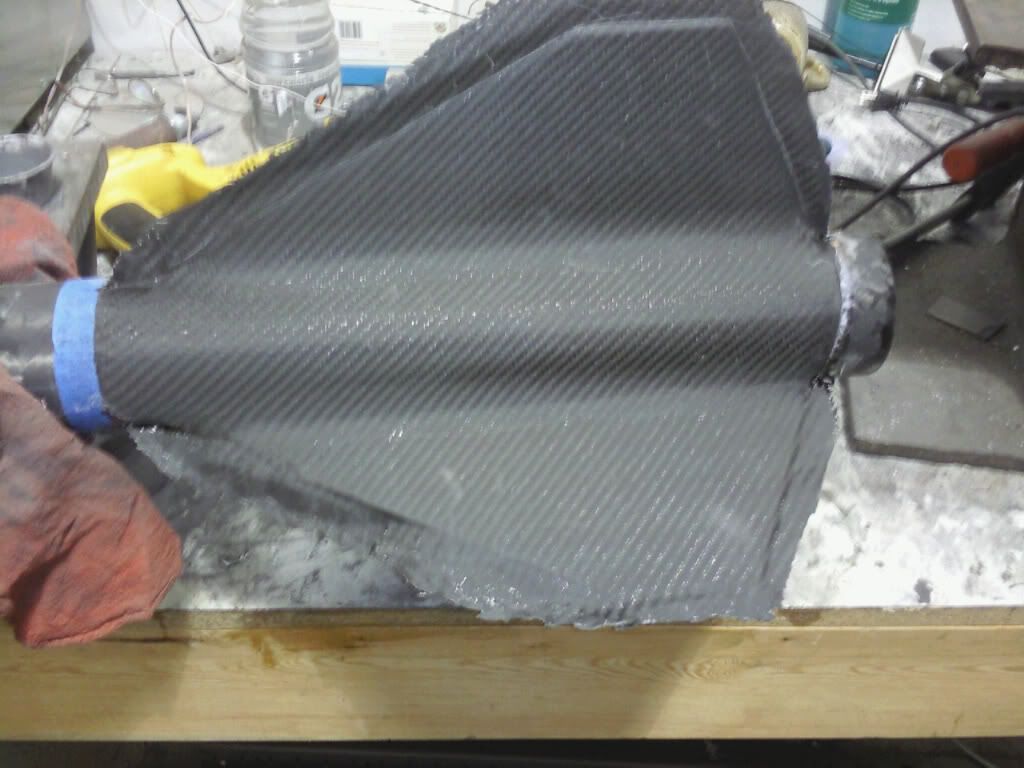

Went to Warrens place to do this last week. "We got in a big fight with the vac. bag." 😡 But it still came out ok. I sanded it and gave it one coat of clear. A little rough yet, but I think the final product will be beeeeeutiful! 8)

Turned out VERY nice Scott. How many coats of epoxy?

JUST 1

Hot, Hot, Hot! Looks real nice, great job! That should be a beast!

Make no mistake, this bird is the shit! Best fillets I've ever seen anyone bring me for a layup. (by the way, aerodynamically, 10% of semi-span is a minimum. 20% is closer to ideal in terms of resolving interference drag at the fillet.)

Two full-sized layers of 5.6oz carbon across fins made from Art's autoclaved carbon plate on PF carbon filament tubing. This rocket will survive anything he can stuff into it. oh yeah, that finish layer looks killer.

Warren: I'd be curious to see a reference for that (the interference drag). Everything I know about interference drag (which is admittedly not much, but it at least includes the basic mechanism) and boundary layers (about which I know far more) would indicate that optimum fillet size would be independent of fin span, and would be more related to fin chord, length of body ahead of the fin, rocket finish, and airspeed. I don't know any exact relations, but I can't think of any way in which it would be related to span (especially for supersonic).

Chris, I'm far from knowledgeable about this. I had the question myself a number of years ago and so I asked the venerable Henry Spencer (do a Wiki search on him if you've never heard of him...) I can probably dig up his reply which has all sorts of the math you're looking for. Boiled down, what I posted is the essence of what he told me.

I have very little knowledge or interest in aerodynamics or mechanical engineering issues. I build things and quite frankly, I do most of it by rules-of-thumb, seat-of-the-pants or just a general overkill approach. Now electronics and software is a completely different matter.

That would be interesting if you could find it. I certainly am not that well-versed on interference drag, and I'd love to know more about it.

Warren: I'd be curious to see a reference for that (the interference drag). Everything I know about interference drag (which is admittedly not much, but it at least includes the basic mechanism) and boundary layers (about which I know far more) would indicate that optimum fillet size would be independent of fin span, and would be more related to fin chord, length of body ahead of the fin, rocket finish, and airspeed. I don't know any exact relations, but I can't think of any way in which it would be related to span (especially for supersonic).

What?! 😯 Look...Just put a bigger motor in it, and even that drag crap cant keep up!!! 8)

Some day...

But keep sending the rocket porn!

Just gorgeous, drool...

Chris, as always you are right - or at least righter than I am in the explanation. It is related to the combination of airframe diameter, fin root chord length and semi-span. I still haven't found the email with the specific math, but did drop another line to Henry and he popped that off in about 10 minutes following my email.

W

JUST 1

I ordered 1 pint of that Cotronics high temp epoxy. 600 deg f. $90.00

Definitely be scraping every last drop off the bench with this stuff.

1 gallon was a deal at $320.00

I wanted to try it first, before I bit that though.

I would have to give it its own room in my house to keep it safe!

I was thinking about it for my top coat.

Might not peal at mach 2. 8)

Bad thing is it needs to be cured in an oven.

Any body have an oven 6 feet long? 😕

That is a serious question.

one thing leads to another. 😉

Old school ovens for curing rockets were refrigerator boxes lined with aluminum foil and a few 100 watt light bulbs suspended inside. Properly sealed, you'd be amazed at the heat produced. Otherwise, Art had access to two large autoclaves but I think he's given notice of un-employmental-ability to Scion.

JUST 1

I ordered 1 pint of that Cotronics high temp epoxy. 600 deg f. $90.00

Definitely be scraping every last drop off the bench with this stuff.

1 gallon was a deal at $320.00

I wanted to try it first, before I bit that though.

I would have to give it its own room in my house to keep it safe!

I was thinking about it for my top coat.

Might not peal at mach 2. 8)

Bad thing is it needs to be cured in an oven.

Any body have an oven 6 feet long? 😕

That is a serious question.

one thing leads to another. 😉

It may be too late now, but I'd recommend the room temperature curing version that is good to 500F. I got the 600 F one that doesn't cure at room temperature (actually it does, but it take a couple of months) and it's a major PITA because all your mixing cups, tools, work area, etc. is goopy for months, or at least mine were. 😳 I was used to just popping the cured epoxy out of my mixing cup after a couple of days. Plus, you will need to run your vacuum bag into the oven. Oven curing is easier if it's just a post-cure.

For an oven, you can have a space heater blow into a cardboard box and get it up to 150 or so. If you just leave bare carbon in the sun and out of the wind it can get to 180. I've used my kitchen oven for a post-cure to 250, but of course that wasn't for a 6' rocket. I've been thinking of getting the foil-backed foam from Home Depot and making a real oven, but I haven't needed to do that yet.

Bad thing is it needs to be cured in an oven.

Any body have an oven 6 feet long?

I do but it does requires assembly. It is regulated to 210F and has internal fans for forced air heating. The heated chamber is about 2'x2'x7' and it is capable of having the parts in a vacuum bag while curing.

Doug