After more than an hour of prep, I'm about ready to mix some epoxy:

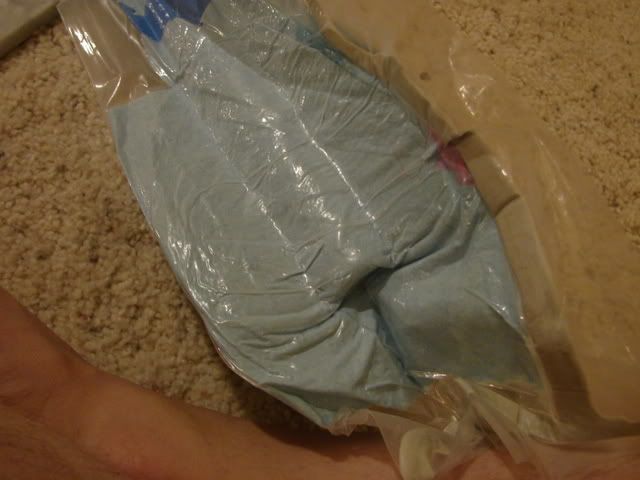

This time I remembered to close off the ends of the tube so the vacuum bag doesn't push the layup into the tube.

Here's the tube after it came out. I sanded it a bit and hit the middle part with some clear coat. It's almost 13" long, and 29 grams. It seems much stiffer and stronger than it needs to be. But I guess that means it's about right.

Actually, it probably is much stiffer and stronger than it needs to be 🙂

I can tell you from personal experience that this is way overbuilt - my SSS from 2006 used 2 wraps of 2oz carbon for the tube (it ended up quite literally paper thin), and it was surprisingly flexible. It survived the up part just fine, though I never found it.

Looks great so far by the way 🙂

Pictures from Christmas eve:

Needs more shop towels to sop op the excess resin. Note to self: The vacuum bag can never be too big

Vacuum bagging done

Christmas morning. Time for pliers.

First look at the layup quality.

The next are two pictures of the same part of the rocket. The outer surface is actually quite smooth and wrinkle-free, but the uni carbon apparently has some waviness within the layup:

After some more rough trimming, I re-weighed it and it looks like I added 5.8 grams to the fins. It will probably be down to about 4.5 by the time I get done sanding. But first, time for breakfast and some some post-curing in my high-tech composite post-cure oven:

Chris,

Do you remember what the tube weighed? Did you wrap the carbon over cardboard, or a fully-removable mandrel?

When I do a 38mm version of this, there aren't any thin Apogee tubes to lay up over, so I'll have to do it directly over the motor casing. What are people's favorite methods of prepping the motor casing for release? Thin, smooth, and no adhesion to the motor case is what I'm looking for.

I used a J570 case wrapped with 8 or 10 wraps of .001 mylar release film to make 38mm carbon tube. Just enough slop for the motor to slide in and out easily.

Warren

How was the release film held in place? And where did you get it?

Release film from Advanced Composites or Fiberglast.com. I just wrapped it tightly around the case and then started wrapping the wetted-out fabric around it. After I did 3 wraps, I wrapped peel-ply, breather and then shrink tape around it. I think I used a little glue stick so that the first wrap stayed in place. It wasn't hard to remove the case after the cure most of the time (I use West Systems, so no post-cure heating). One tube I needed to shove in the freezer to pull out the case.

Warren

I always wondered what to do with those build-a-bear boxes laying around......

So are you using friction or motor retainers? Warren, how thick do you think the whole wrap was that you put around the motor case?

Adrian, did you notch the body tube any for the fins to set down in?

Thanks

G

After the first go-around with the sandpaper, the fins are down to 4.1 grams and 0.06 thick. The two outer layers of thin fiberglass are mostly gone. I still have some low spots where the uni tape had some gaps, and so I think I'll experiment with some some fiberglass matt veil I got on my last order. The fins are plenty strong now, at least as rigid as I was hoping they would turn out to be.

Greg, I'm going to use friction. No notches for the fins. But most of the fin thickness is in the layers that wrap over the fillet, so if they ever break off, it will be in the middle of the fin.

Some other folks in the club have made a nicer looking rocket, but not me.

Some other folks in the club have made a nicer looking rocket, but not me.

Hope the fins are on straight 😉

Very nice Adrian

Thanks. I think I'll be making carbon fiber rockets from now on. Here are some things I learned along the way:

Doing the layup with the marble floor tiles, it's very easy to get good quality, so in the future I would do all but the last layer of tip-to-tip carbon in one layup using the tiles. And the extra step of making two different fiber orientations within the same layer isn't really necessary, given all the layers required. So I could just make a continuous plate with the layer orientations I want, and then just cut it out.

Using CA glue to attach the fins, followed by epoxy-microsphere fillets, worked well. I'm still working on the best method for getting the fins on perfectly straight, so if anyone has a good tip, let me know.

I think the final layup would go a little better by having fewer layers to put on at the end; it was a struggle getting all of the CF to lay down on the fins and get the peel ply, shop towels and everything wrapped up in the vacuum bag before the epoxy started going off.

Chris,

Do you remember what the tube weighed? Did you wrap the carbon over cardboard, or a fully-removable mandrel?

I did it using my 29/360 case as a mandrel (wrapped it in mylar, then CF, then more mylar, then heat shrink, then the whole works went into the oven at 180f for 8 hrs). It was phenomenally light - final was 11.7 grams for 13" of tube. I cut it down to 8.5" for the rocket, and that weighed about 8g IIRC (I'm not positive about that weight - the pre cutting weight is definitely accurate).

Here's a pic of it after it was cut down to 8.5" (this is exactly how it came out of the oven - nothing had been done to it at this point other than simply trimming the ends):

Cool. You should try it again, this time with a Parrot and a Beeline, and go for the F, G, and SSS contests.

Make a cardboard fin template for the alignment. Can't use CA though.

W

I spent all of Saturday doing calibrations on a 250-G prototype version of the Parrot V2, tweaking the flight code to avoid numerical overflow with the higher-G sensor, rebuilding the av-bay, and doing final prep work on the rocket. By the time I was done, it was all we could do on Saturday to head up to the Comfort Inn in Wellington and be ready to fly today.

Too bad, too, because it was really windy this morning. I did a test flight ona C6-7, which went well. The Parrot worked like a charm with deployment right at apogee, and I recovered the rocket without a scratch. It's named Barack-it. I didn't want to try the 3-4 mile recovery that would have been necessary with the H238 in these winds, so it will have to wait for next time.

Anyone have information on Tripoli Colorado's "Spring Fling?" Is the 6000' waiver likely to be extended to 14k?

Here is a graph of the deployment data:

This chart is really busy, and I haven't done much to make it more understandable yet, but here's a quick first take on it:

The little square wave lines at the bottom came from the flight event register that is recorded on-board the Parrot. It tells you what the Parrot thought was going on throughout the flight. The deployment logic is programmable now to use any simultaneous combination of the events you see on the chart. The orange line indicates the ignitor continuity that was measured and recorded during the flight. When it dips low, current was flowing through the ignitor. It fired in response to the accel-based apogee detection (green line), which appears to have nailed it for this flight.