ROOT CAUSE FOUND - See my post on 2nd page

I could use a little help from folks (especially those who have actually done HP staging) in doing a post-mortem and brainstorming a bit on my my two-stage flight at MHM. The flight appeared to be succesful (see pictures in the following post) and all electronic functions (4 avbays with backup systems) and charges worked as planned, however the sustainer came back without the fin can section, which included the motor hardware and ignition avabay. The 15 foot long 1/4" tubular kevlar cord from Giant leap snapped at the simple slip-knot loop for the sustainer drogue chute. It was located about 2-1/2 feet from the altimeter avbay. The quick link was missing along with the drogue. Its obvious that the deployment of the drogue was premature and at high speed, however, the question for this forum is.... WHY did it occur? The goal here is to have a good scientific or otherwise reasonable explanation of what occured and to not repeat the occurance in the future.

Note: the sustainer's RRC2X read 5818 feet ❓ and the RRC2-mini was accidently reset in trying to read its memory as it only read 319 feet. These readings are not even in the ball park of the altitude it should have achieved. The booster's Adept Alt25K read 2800 feet for the booster' s apogee. It is possible that the rocket never got higher because of the separation, but many onlookers with experienced eyes said the rocket trail went much higher than what was indicated. Rocksim calculated the burn of the booster stage (Ricky) to stop at 2200 feet and the upper stage (Micky) to stop at 7000 feet. The Twins were supposed to achieve over 14,000 ft. FYI, this rocket was named after myself and my twin sister.

I obviously do not appreciate or understand totally the drag separation forces involved, as I keep encountering this issue as I make more powerful and complex rockets. Hopefully, if the fincan is recovered it will provide more data.

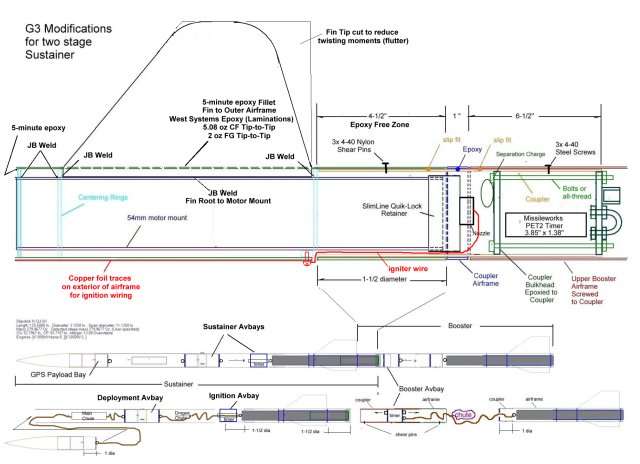

This was my 1st two stage HP rocket which was an evolutionary project based on two Performance Rocketry G3 kits. It started as my L2 Cert bird and grew to include another stage. Another design permutation (next month) will have a boosted dart. The construction assembly is pictured below (the drogue shock cord broke between the igniter avbay and the deployment avbay):

Full size PDF:

http://www.telerover.com/rockets/MS/G3_mods_two-stage_Rev8.pdf

Possible failures of the shock cord and/or premature separation:

1- Shock cord length not long enough? 15 foot was used, 20 feet is now available. I used 40 feet on my L3.

2- Shock cord diameter not sized correctly? The choice was 1/4" or 1/2" from Giant leap. A 3/8" option would have been nice.

3- Inadequant pressure venting of the airframe? a 2mm (.080") hole was at the end of each tube, but I may have covered one with vinyl. The internal pressure could have ben added to the drag separation forces.

4- Inadequate static vent holes in altimeter bay, causing premature deployment? There were three 1/8" dia holes in the 3" x 9" long avbay.

5- Insufficient mach delay time? I programmed in 12 seconds on both the RRC2X and RRC2 mini. The rocksim maximum velocity was Mach 1.2.

6- Too small of shear pins? I used 3 equal spaced 4-40 nylon screws. In its one stage configuration 2-56 screws were used.

7- Should have used accelerometer based controllers rather than barometric sensor based controllers?

8- Your thoughts? 💡

I've ordered parts to build it again so i can get it right next time. Failure is not an option.

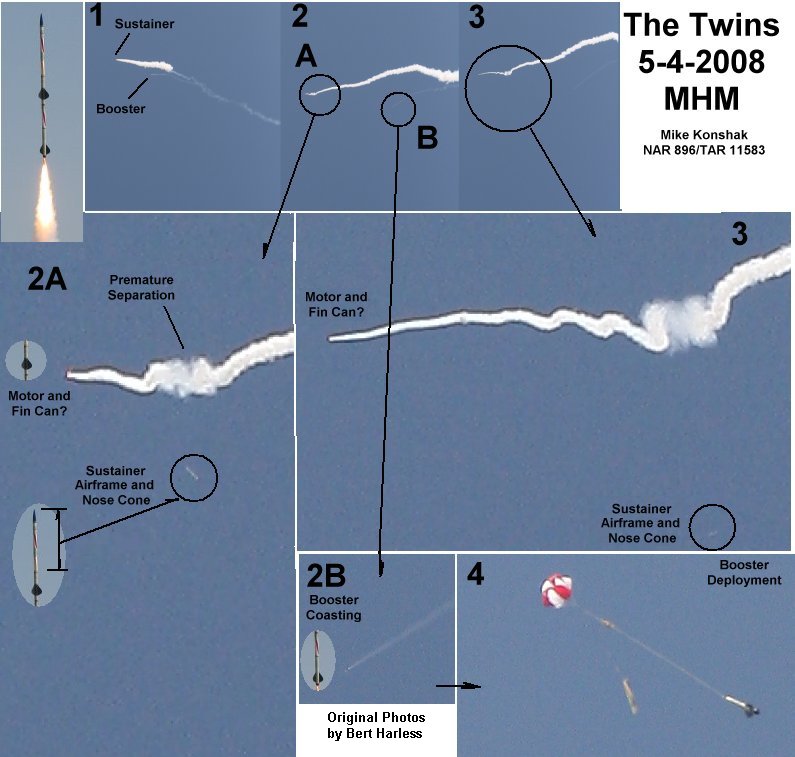

The Launch of The Twins

The ignition of the sustainer, Micky. The booster, Ricky, seen coasting to its apogee

Pictures courtesy of Bert Harless

Looking at some of my dad's shots, it's hard to tell, but it's possible that it came off as a drag separation right after booster burnout. It looks like it gets shorter at that point, but it's hard to tell for sure, as the rocket is quite far away at that point.

Looking at some of my dad's shots, it's hard to tell, but it's possible that it came off as a drag separation right after booster burnout. It looks like it gets shorter at that point, but it's hard to tell for sure, as the rocket is quite far away at that point.

I'd like to see a smoke trail of what happened after 2nd stage burn-out. Can you ask him to send them to me please? Thanks Chris

Sure. I'll tell him to contact you.

One thing that I would suggest from your design is on your booster you separate it in the middle of the tube. I would suggest ejecting your chute out the top only because when you make that extra break in the rocket you have more chances of the rocket shaking and possible folding from the forces. And folding at the joints happens often on two stages because of the length. If you want you could talk to my dad Eric Parsons, he successfully did a two stage a few years back.

... And folding at the joints happens often on two stages because of the length.

That was a major design consideration. Thanks for bringing it up. In order to improve the longitudinal stability, the coupler/airframe interfaces in the middle of the rocket all had a 1-1/2 diameter (4-1/2") overlap vs the normal one diameter (3") overlap. It was a fairly rigid rocket when carried in its all-together.

Bert sent me some high resolution pictures whiuch I was able to zoom in on and get some revealing information, Thanks Bert! It appears the boost section of the sustainer was aerodynamic for a while after it came apart from the rest of the sustainer. Now I know why the altimeter(s) read so low.

Awesome photo analysis. Very interesting. So I guess it boils down to: Why did the sustainer separate prematurely?

The separation happened with the sustainer under thrust, so drag separation should be ruled out.

Could a lack of venting cause enough pressure to overcome the motor thrust and the shear pins? It seems unlikely but a quick calculation could help answer that one.

A premature firing of the charge remains a possibility. Could you tell anything about whether the charge fired while the pieces were together by the post-flight condition of the upper part of the sustainer?

Some recorded data would really go a long way here.

Well this explains what I saw when I thought I saw a fin had shredded off. It wasn't the fin the sustainer BT and NC falling off. I hope your able to find all the part so you can figure out what happen before round two flies.

Ron

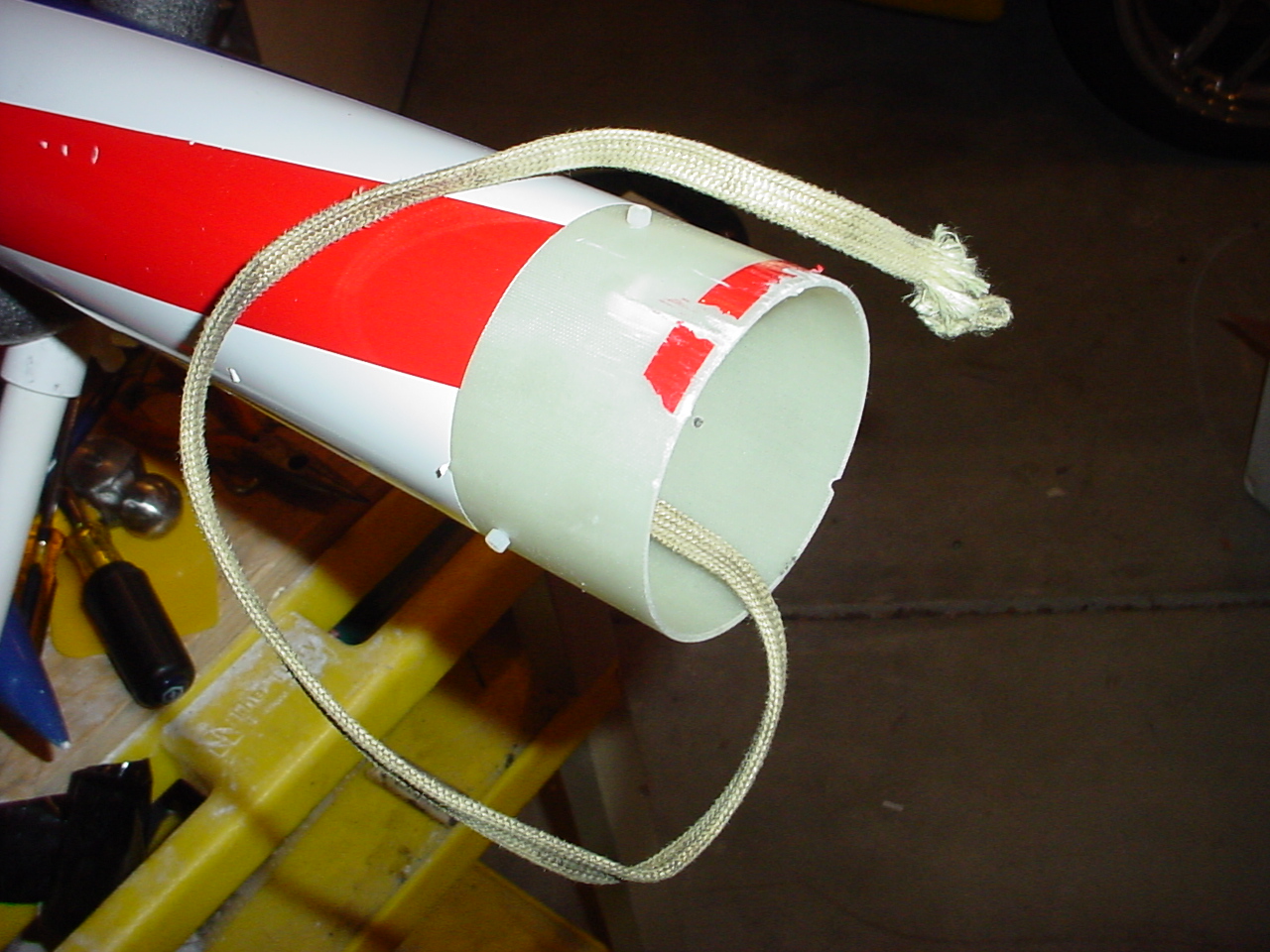

Here's a picture of the fin can. You can see how much overlap I have on the coupler containing the igniter timer. The coupler was attached to the fin can with 3 4-40 steel screws, and three 4-4- nylon screws were used for shear pins. The exposed all-thread was covered with vinyl tape before final assembly.

The cord coming out of the igniter avaby was directly attached to the motor by a custom eye-bolt I welded up. (to save space).

Full Size:

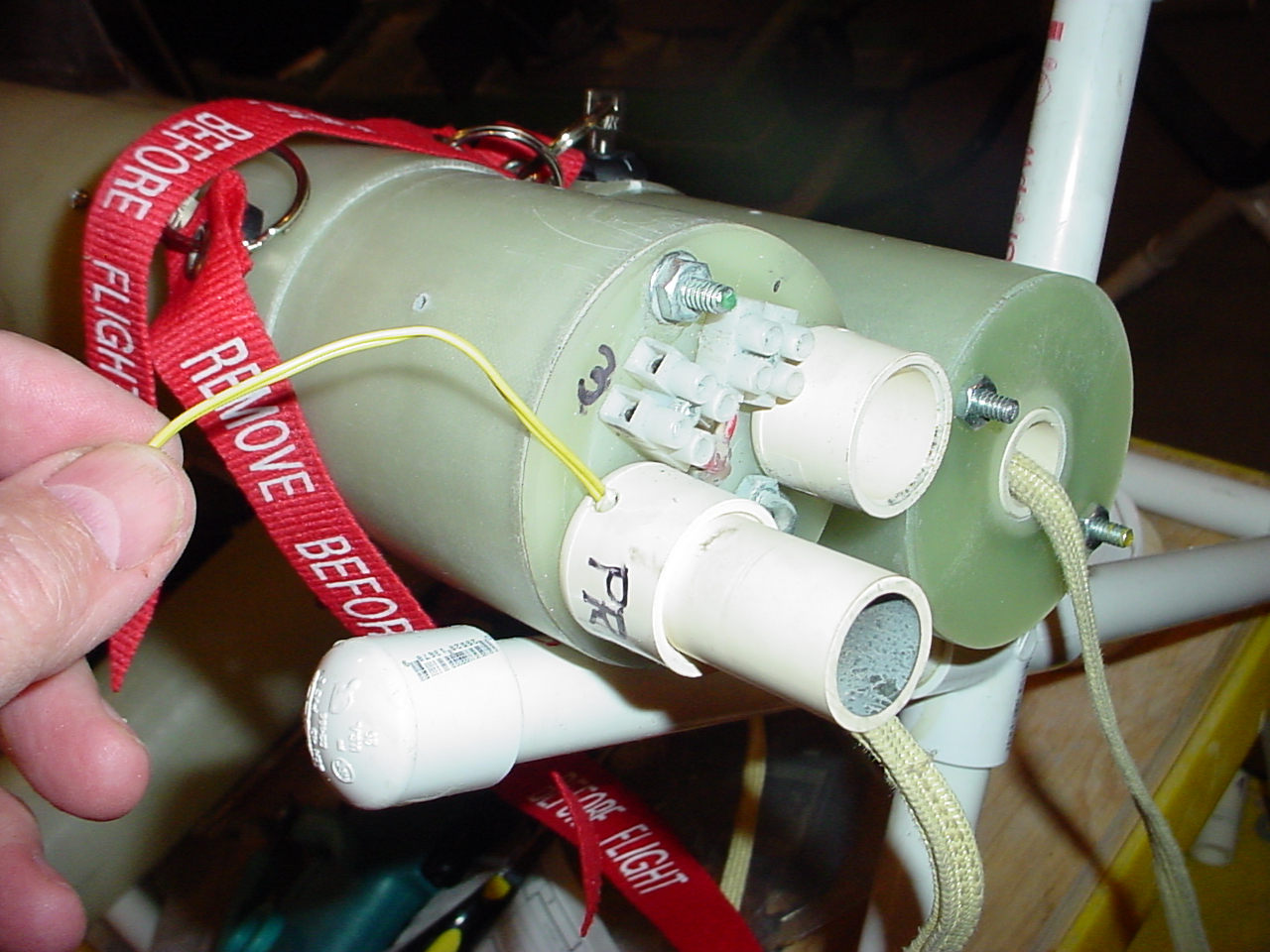

I documented the construction of this bird fairly well, so here's a shot of me putting in the actual shear pins prior to flight.

Full Size:

Here's the chute, blanket, before being stuffed in the tube

Full Size:

Full Size:

And that same cord after it was ripped apart at the slip-knot. The quick-link also gave way and dissapeared. You can see the crack in the airframe where it tried to zipper. The heads of the shear pins are still in the airframe (which was threaded - the coupler had clearance holes):

Full Size:

Awesome photo analysis. Very interesting. So I guess it boils down to: Why did the sustainer separate prematurely?

The separation happened with the sustainer under thrust, so drag separation should be ruled out.

Could a lack of venting cause enough pressure to overcome the motor thrust and the shear pins? It seems unlikely but a quick calculation could help answer that one.

It appears that one of the 1/8" vent holes was blocked, the one on the fin can end.

Using the pressure calculator at http://www.digitaldutch.com/atmoscalc/

The pressure at the N Pawnee (5500 feet at 50 degF) site would be 12.0 PSI

At 5800 AGL or 11,300 feet ASL, the pressure would be 9.6 PSI or 2.4 PSI difference.

A 3" airframe has a cross sectional area of 7 sq inches

2.4 PSI X 7 in^2 = 16.96 pounds-force.

If I enter that data into the calculator at http://www.mrhq.org/software/clcltrs/clcltrs.shtml it says it will safely shear two 4-40 nylon screws. So maybe I was right at the limit. six 4-40 screws would have been better or a set of 6-32's.

A premature firing of the charge remains a possibility. Could you tell anything about whether the charge fired while the pieces were together by the post-flight condition of the upper part of the sustainer?

No, both charges were set off, and I assume since this setup has flown four times before, they went off at the right time (at the apogee detected after separation). Could the speed have affected their triggering? Don't know. I had 12 seconds of mach delay in it, and separation appeared to have occurred at about 6-7 seconds.

Maybe its a combination of the shear pins partially drag separating at the end of thge booster thrust, then getting kicked by the sustainer motor. I'm leaning toward blaming too light of shear pins and not enough vent hole area at the moment. I also think that going to an accelerometer based deployment charge would be better past mach.

Keep the thoughts coming!

Mike,

OOPS, just saw the picture for my question....

Where did the tear actually occur? Did it pull away at the stitching opening the loop up or where?

I was told years ago in a search and rescue class that looping a cord on it's self like that causes a shear point where the strap/cord will actually cut it's self in half. A figure eight loop (common climbing knot) is the best at keeping this force from acting on the strap/cord. In this case, I assumed that's why all of you guys here use the chain repair or add on links.

Nice job with the preflight closeout pictures. That's what we do in the spacecraft industry; I should do that myself.

I'm a little skeptical about the pressure separation, because it would have to overcome the following factors:

-The sustainer's thrust was compressing the two sections. What was the predicted acceleration at that point in the flight, and how much does the upper part of the sustainer weigh?

-The single vent hole would have reduced the internal pressure before the event (Vern's site has some equations for this)

-If the top section did start to move apart, the overlap section is so long that the volume would increase significantly, lowering the pressure further.

-The drag of the top section should have helped to push it down.

If you add up all the forces on the top section at that time of flight, I bet there's a lot of compression holding the two pieces together, even without venting.

Did Rocksim predict that the sustainer would go through Mach? If so, what part of the flight? Maybe you can use a shop vac or something to verify that in its current state the altimeter's Mach inhibit timer really would prevent deployment at that point in the flight.

Was the drogue deployment av bay sealed off from the aft section of the sustainer? Just speculating here, but did the bottom of the upper section of the sustainer seat firmly against the top of the lower section's outside tube when the shear pins were in place? If not, perhaps compression of the two sections during the two burns helped to shear the pins. And if the two sections compressed into each other during the burn, it would show up as a pressure spike (and false apogee) in the altimeter if there was a leak path into the sustainer's av bay.

Here's the Rocksim flight profile showing Mach 1.17

http://www.telerover.com/rockets/MS/Slipstick_IV_FlightProfile.pdf

The boost section of the sustainer weighed 6 pounds and the rest was 4 pounds. The booster itself was also 6 pounds.

All orifices in the avbay bulkheads were sealed sealed with hot glue. The bulkhead to caps aren't watertight but they do overlap internally and externally.

Full Size:

You might be onto something where the sections may not have been put together tightly when the holes for the shear pins were matched drilled, which could have caused some weakening under initial booster thrust. The K700 had 143 lbs thrust which would have been about 9 g's (143 lbs-f /16 lbs) on the rocket, extrapolating to the joint in question would have put 36 pounds of force (4 lbs x 9G's) on the 4-40 screws. They could have partially sheared.

The avaby electronics did get some charge residue in them from an earlier ground test. No one that I've talked to has said that the baro sensors would have been affected by that.

A broken forward closure could have caused the separation as there is an opening from the fin can through the igniter avabay (a central tube that the shock cord ran through) which could have pressureized the drogue section. See the above picture.

Finding the tail would tell the tale. 🙄